-

Common Roll varieties are cast steel roll, cast iron roll and forging roll three categories

[2020-07-03]There are many kinds of rolls. There are cast steel rolls, cast iron rolls and forged rolls. There are also a few cemented carbide rolls in profile rolling mill. Forming method, casting roll and forging roll; casting roll is the type of roll produced by directly pouring the molten steel or molten iron into the mode of production. Casting roll can be divided into cast steel roll and cast iron roll

-

Hot Roll is mainly cast iron roll and cast steel roll

[2020-07-03]Hot Roll is mainly cast iron roll and cast steel roll. Cast Iron Roll is divided into nodular cast iron, chilled cast iron, infinitely chilled cast iron, cast steel is divided into 70Mn, 70Mn2,70MN2MO, 75CrMo, 140CrNiMo, 160CrNiMo and other materials. The performance and quality of the roll depend on its chemical composition and manufacturing method, and the use effect of the roll in the mill is a

-

Roll can be divided into several categories of material

[2020-07-03]Roll is divided into cast iron roll, cast steel roll and forged steel roll according to material. The carbon content of cast iron roller is 2. 50 / 0 ~ 3.5% , according to the main materials can be divided into four categories: chilled cast iron rolls, infinitely chilled cast iron rolls, high chromium cast iron rolls and nodular cast iron rolls. The common structure of cast iron roll can be divide

-

The working condition of roller is more complex

[2020-07-03]The working condition of the roll in the rolling mill is complex. The roll will produceresidual stress and thermal stress in the preparation process before manufacturing and using. It is further subjected to a variety of cyclic stresses, including bending, torsion, shear, contact and thermal stresses. The distribution of these stresses along the roll body is uneven and constantly changing due not

-

Gold label takes you through the cold roll manufacturing process

[2020-07-03]The main links of the cold roll manufacturing process are melting, forging, heat treatment, processing and inspection. In the course of cold rolling, the cold roll has to bear a lot of rolling stress. In addition, the welding seam, inclusion and edge crack of the rolled piece have problems, which easily lead to an instantaneous high temperature and make the work roll subject to a strong th

-

How to choose the material of roller

[2020-07-03]1.The selection of work roll material the work roll (R1) in the front section of roughing mill: the Work Roll in the front section of roughing mill must have strong toughness, wear resistance and hot cracking resistance. The hardness range is about HS40 -- 55. 60CrNiMo cast steel rolls are generallyused.

|

|

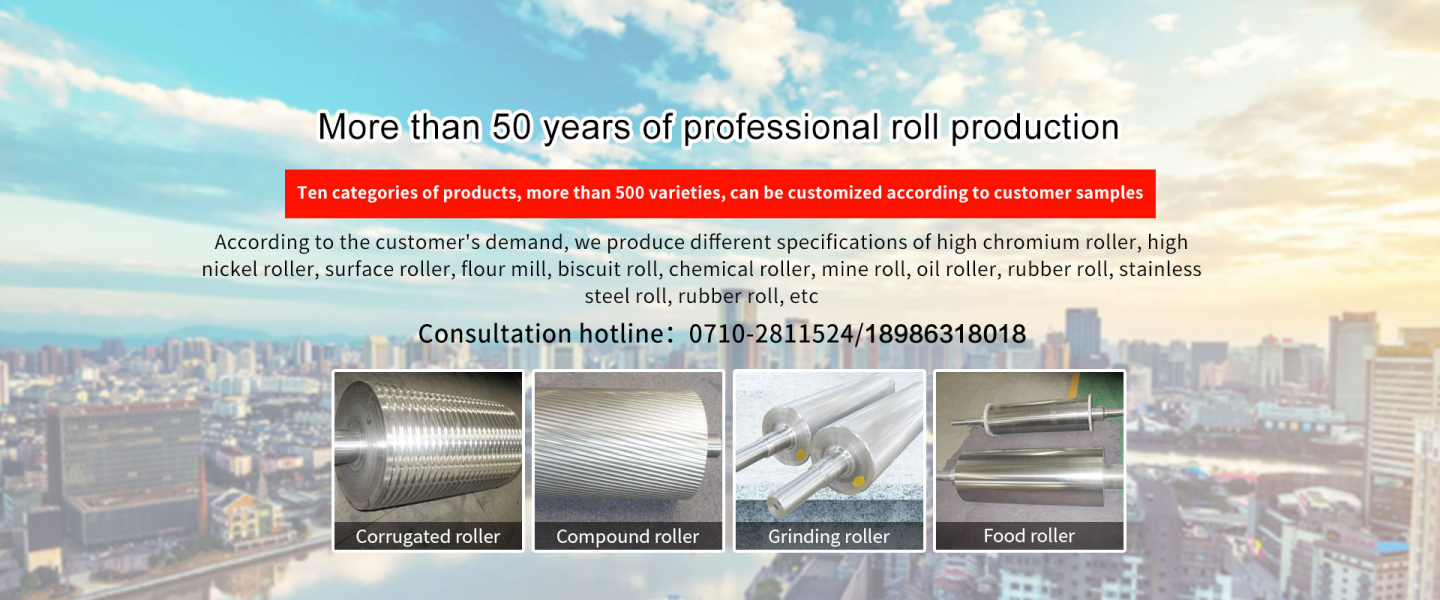

Product display Roll display |

Contact us Contact: Mr. Fang Tel: 18986318018 Address: South of Diamond Avenue, Xiangzhou District, Xiangyang |

About us About us Honor and qualification |